Softstar Shoes

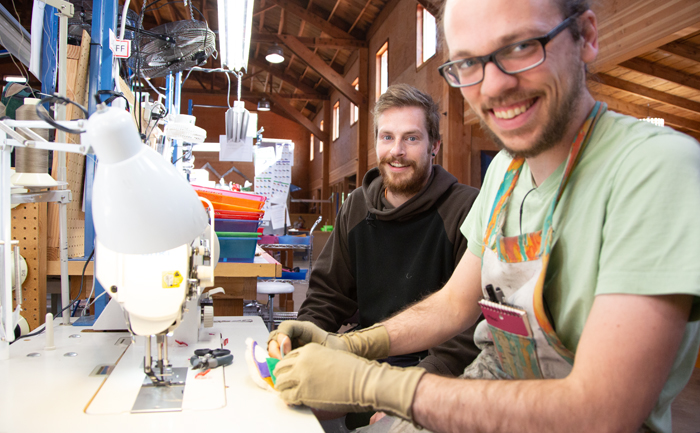

Sustainable practices are a guiding force throughout the recently renovated workshop in Philomath.

Every day at exactly 9:47 a.m., the shoemakers stand and take a three-minute stretch break. Music plays in the background as the employees use a collection of bars, cylinders, and other equipment to keep their muscles warm and limber.

It may sound small, but stretching, along with job rotations throughout the day, are key components of the safety culture at Softstar. Each shoe is handmade, which means the workers must protect against strains from repetition and overuse.

Depending on their expertise, workers may rotate to two or three different areas each day. Customer service employees are also on rotations to help them develop skills in production.

During the busy holiday season, Softstar has a physical therapist that visits to focus on stretches for the hands, wrists, arms, and shoulders. The workshop also has adjustable machines and ergonomic chairs, so rotations from station to station are seamless.

Guiding principles

Softstar Shoes has been around since 1985, when it began making soft, leather shoes for children. Today, they make many lines of flexible, minimalist shoes for all ages.

Sustainable practices are a guiding force throughout the recently renovated workshop in Philomath, from production to the packaging shipped to customers.

Softstar calls it "walking lightly on the Earth."

This includes sourcing local materials within the U.S., recycling, creating cat toys from scraps for charity, and partnering with other retailers to use recycled materials. For example, a local bike shop provides material that is used for the toe caps in one of Softstar's adult running shoe lines.

The workshop was renovated in 2017 out of an abandoned roller-skating rink. It boasts LED lighting, radiant heat flooring, and is powered by wind and solar energy.

To learn more about Softstar Shoes, visit softstarshoes.com